Environmental Sphere

Y-EMEA is steadfast in its commitment to key principles outlined in the Environmental, Health, and Safety Policy, embracing a proactive stance to ensure compliance with environmental laws and other relevant requirements. This commitment extends to preventing pollution and consistently improving our environmental performance through the adoption of cost-effective practices, seeking to eliminate, minimize, or mitigate environmental impacts. Every employee, contractor, and visitor share the responsibility of upholding this policy

3 Spheres

In the following sections we address initiatives that contribute to each area.

Key facts

Environmental soundness

All manufacturing sites in operation have successfully maintained their Environmental Management Systems (SGA) certification under ISO 14001. Several environmental performance indicators are diligently monitored on a monthly basis per manufacturing site and yearly per office. This practice ensures a thorough assessment of Y-EMEA’s eco-efficiency. Based on the performance results, we develop action plans to further enhance our environmental performance, underscoring our commitment to ongoing improvement and sustainable practices.

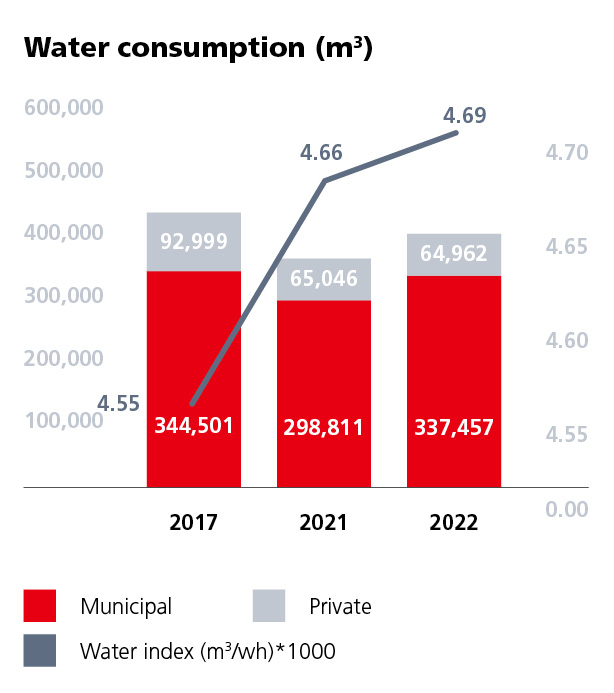

Water consumption

During the Business Year, Y-EMEA's total water consumption amounted to 402,420 m3, comprising 84% municipal water and 16% from private water sources (water wells). This represented an 11% increase compared to the previous year, attributed to the recovery in business activity, yet still reflected an 8% reduction when compared to the baseline year. Y-EMEA remained committed to implementing measures for optimizing water consumption including awareness programs for employees, the installation of water-efficient technologies and regular maintenance practices to promptly address and rectify any potential leaks. Further, some plants already have in place systems to recycling and reusing water.

Energy consumption

Our total annual energy consumption comprising manufacturing sites and offices was 425,103 GJ in Business Year 2022 (a 20% and 3% reduction comparing to Business Year 2017 and 2021, respectively). Electricity power is the main energy type we consume in our operations, representing 79% of our energy footprint.

GHS emissions

We measure our annual corporate carbon footprint assessing emissions across scope 1, 2 and 3 in accordance with the GHG Protocol standards. This comprehensive approach allows us to thoroughly account for:

- direct emissions from our operations associated to fuel combustion in buildings, our company's vehicle fleet and fugitive gases from refrigerants (Scope 1),

- indirect emissions from purchased electricity and district/municipal heating (Scope 2) and

- a broad spectrum of indirect emissions throughout our value chain (Scope 3).

During the Business Year we observed a recovery in activity following the post-pandemic period. Overall, our emissions showed a 15% increase compared to the previous year but demonstrated a 16% decrease when compared to the baseline year 2017. Our scope 1 and 2 emissions totaled approximately 34,147tCO2e, constituting 5% of our carbon footprint.

Employees´ awareness

Our commitment to sustainability extends beyond designated sustainability roles. We are dedicated to assisting our diverse workforce in seamlessly incorporating sustainability into their responsibilities. This is achieved through the provision of learning opportunities and the establishment of channels for active participation in our sustainability initiatives. During the period of reporting, in the regions where Y-EMEA operates, several awareness initiatives were carried out dedicated to promoting environmental responsible behaviors and best practices among employees.

Yazaki Tunisia promotes a greener environment

Yazaki Tunisia (YTU) actively participated in the "National Tree Day" celebrations by joining a local civil society's planting campaign in Gafsa city. During this environmentally conscious initiative, YTU colleagues contributed to the cause by planting 256 saplings, aligning with their commitment to environmental responsibility and corporate citizenship.

Think and Act Green: Green Ambassadors

Y-EMEA has initiated the establishment of Green Ambassadors at various locations – employees that serve as role models, inspiring colleagues to actively engage in environmentally responsible practices and contribute to Y-EMEA's overarching sustainability vision.

Ukraine team planted a public fruit tree avenue

The Yazaki Ukraine plant in Uzhgorod (YUL) has undertaken a commendable initiative to enhance its surroundings. In collaboration, local colleagues planted 15 apple seedlings, transforming the area into a more inviting space for the local community. This activity, bridging environmental protection, utility, and aesthetics, reflects the team's commitment to their community.